About Ambience Water

Your Trusted Partner in

Water Purification Solutions

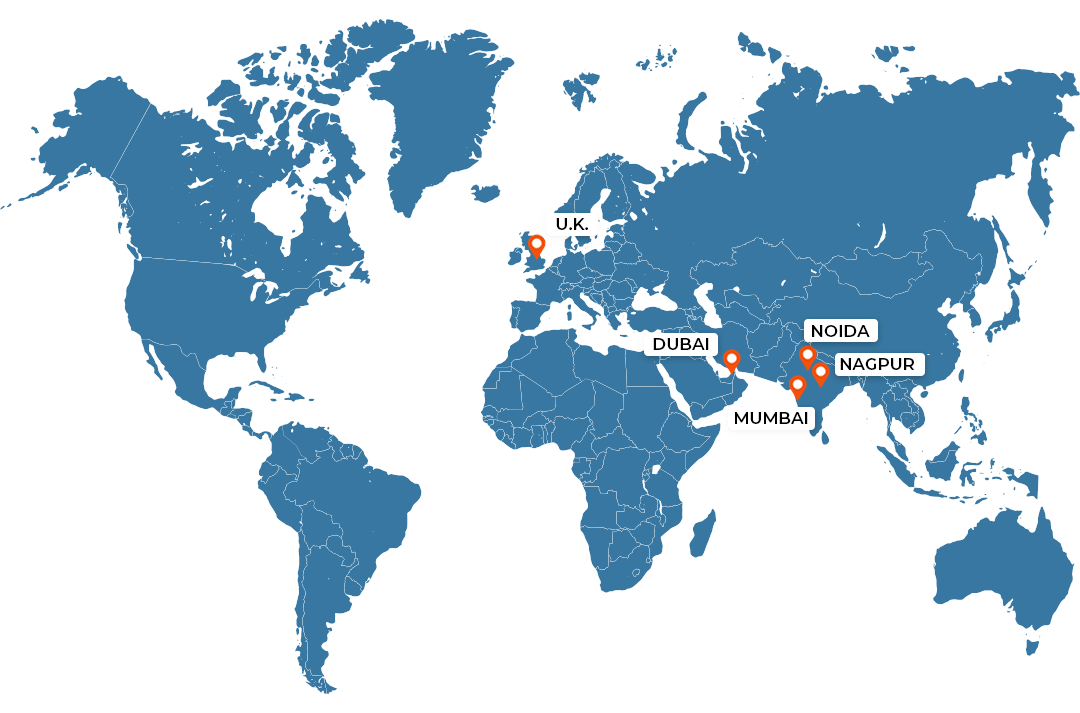

Welcome to Ambience Water Solutions & Marketing Ltd., a distinguished member of the Ambience Group since 1997,

renowned for our unwavering commitment to excellence in water treatment solutions. With over two decades of

industry expertise, we specialize in delivering cost-effective and efficient solutions across a diverse range

of sectors.

Our extensive portfolio encompasses state-of-the-art technologies tailored to meet the specific needs of

industrial, commercial, and domestic clients.

Read More